Mining

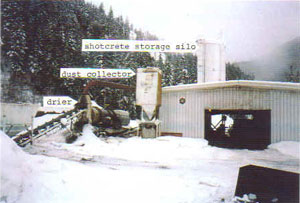

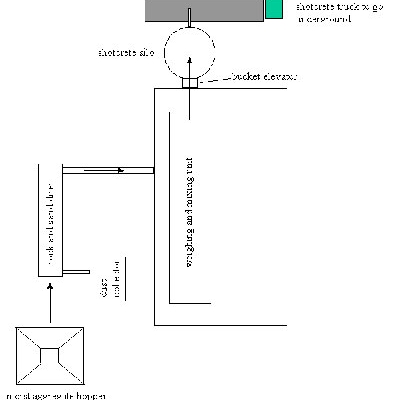

On-Site Dry-Shotcrete Production at Kemano Plant – Kitimat, BC

| Project: | Intake and exhaust tunnels and powerhouse for the KEMANO Hydroelectric Plant (near Kitimat, BC) |

| Year: | 1990/1991 |

| Owner: | Alcan – K.C.P. (Kemano Completion Project) |

| Contractor: | Foundation |

| Client: | Foundation |

| Volume: | Approximately 6,000 cubic yards in 200 days |

| Operation: | Target Products Limited designed, built and operated its own batch plant which was erected at the site.

|